Use the Sunbelt Rentals App

Find, rent, and return equipment, right at your fingertips

Trench Safety Considerations

Learn about the potential dangers and how to mitigate them through proper planning and safety protocols. Click any of the links below to learn more:

Trenching and Excavation Safety Basics

According to the Occupational Safety and Health Administration (OSHA), all open excavations, including trenches, are subject to their standards, regardless of size. Cave-ins are the most fatal excavation-related incidents that construction workers can face, with the weight of a cubic yard of soil being as much as a car. To prevent these incidents, OSHA requires the designation of a competent person, the creation of protective systems, and pre-planning when needing to use a trench box.

Competent Person

As stated by OSHA, a competent person is designated by the employer and trained to recognize both existing and potential hazards at the worksite. They must be able to take corrective measures to eliminate these risks promptly. Several critical tasks assigned to the competent person include:

- Soil classification: Evaluating the soil type, determining its stability, and identifying any potential hazards that may arise due to soil conditions.

- Protective systems inspection: Shoring, shielding, and sloping systems must be thoroughly checked to ensure they are installed correctly and provide adequate protection.

- Designing structural ramps: Ensuring they are regularly inspected to be safe and stable for workers and equipment to use.

- Monitoring water removal equipment: Confirming proper operation to remove water from the excavation site as required.

- Conducting site inspections: Regularly assuring that all workers are following safety procedures, and that all equipment is in good condition and being used correctly.

By undertaking these tasks, a competent person can greatly reduce the risk of accidents and injuries at excavation sites and ensure the safety of all workers. At Sunbelt Rentals, we offer courses to obtain certification as a competent person and to increase awareness of confined spaces, which helps ensure that the safety measures outlined in the general OSHA safety guidelines and standards are properly observed on your worksite.

Protective Systems

Determining the right protective system for your site depends on the specific conditions and potential hazards present. According to OSHA standards, any trench that is over five feet deep and not built entirely in stable rock requires a protective system. Protective systems are utilized to prevent cave-ins through the implementation of techniques like sloping, benching, supporting the excavation's sides, or setting up a shield or trench box between the sides and the work area. Employers can consult OSHA standards for guidance on support systems, such as shoring, bracing, or underpinning, that keep adjacent structures stable during excavation.

It is important that a competent person inspects the protective system and adjacent areas before workers enter the site, throughout the shift, and after a rainstorm. Workers should also be trained to identify potential cave-ins. To further ensure the structural integrity of protective systems and other worksite safety measures, consult with qualified safety consultants like our team at Sunbelt Rentals, who are well-versed in general OSHA safety recommendations and standards.

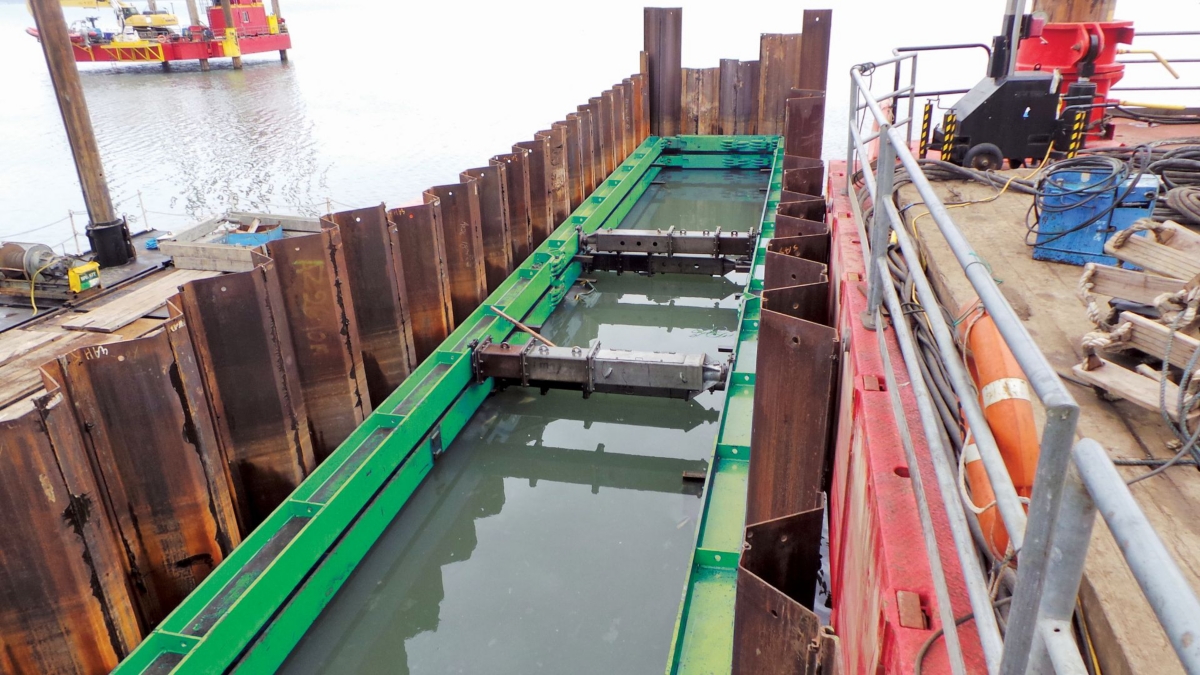

Trench Boxes

Proper planning for the deployment of trench boxes is vital to maintaining a secure work environment, ensuring that the equipment is readily available and meets the excavation requirements. They provide an added layer of protection when protective measures are insufficient by creating a sturdy enclosure within the trench that guards workers against potential cave-ins and minimizes the risks associated with shaky soil conditions.

Understanding the circumstances necessitating trench boxes is critical to ensuring a safe work environment. While measures like sloping, benching, and shoring are vital in preventing cave-ins, trench boxes become necessary when the trench depth exceeds a certain threshold or when the soil composition exhibits signs of instability beyond the capabilities of other protective measures. In shallower trenches where the soil is inherently stable and meets safety regulations, trench boxes might not be necessary. Protective measures like sloping or benching might suffice, in such cases, provided they meet safety standards and are properly implemented.

Incorporating trench boxes into the safety protocol from the outset ensures that the necessary equipment is readily available, properly sized, and compatible with the specific soil conditions and trench dimensions. This meticulous planning and adherence to industry best practices underscore the commitment to upholding the highest safety standards and mitigating the potential hazards associated with trenching and excavation work.

Sunbelt Rentals offers an extensive line of OSHA-compliant trench safety equipment to keep your projects safe and compliant. Our team of industry professionals can help you select the safest, most cost-effective protective system that meets the specific needs of your trench and excavation projects.

Underground Utilities

Excavation work poses a significant risk of damaging underground utilities such as gas lines, electrical cables, water pipes, and telecommunications lines. Accidental contact with these utilities can lead to dangerous situations, including explosions, electrocution, and service disruptions. To mitigate this hazard, it is crucial to accurately locate and mark all underground utilities before commencing excavation work.

Unprotected Trenches

Trenches that are not properly supported or shored up can collapse, leading to workers being buried under the soil and debris. Proper trench protection measures, such as trench boxes, shoring, or sloping, must be implemented to prevent trench collapses and protect workers from this hazard.

Cubic Yardage Requirements

Excavation work often involves the removal of large quantities of soil and other materials. Improper handling of excavated materials, particularly in cases where the cubic yardage exceeds safe limits for equipment or nearby structures, can result in cave-ins, structural instability, or the overloading of machinery. Adhering to appropriate cubic yardage requirements and ensuring proper disposal or storage of excavated materials is essential to prevent accidents.

Utility Lines/Construction Industry Nearby Structures

Excavation work conducted near existing structures or utility lines can pose a risk to the stability and integrity of these structures. Nearby buildings or infrastructure may be susceptible to damage from excavation-related vibrations, undermining of foundations, or unintended shifts in the ground. Proper planning, structural reinforcement, and monitoring are necessary to safeguard adjacent structures and utility lines during excavation work.

Heavy Equipment/Potential Hazards

The use of heavy machinery, such as excavators, bulldozers, and dump trucks, presents several potential hazards, including equipment malfunctions, rollovers, and collisions. Inexperienced or inadequately trained operators can contribute to these risks. Proper training, regular equipment maintenance, and adherence to safety protocols, such as using personal protective equipment (PPE) and implementing equipment-specific safety measures, are crucial to prevent accidents and injuries associated with heavy equipment use during excavation work.

Building a Secure Future, One Trench at a Time

Trench safety is a critical aspect of excavation work that requires careful planning, adherence to safety protocols, and comprehensive training for all involved personnel. Sunbelt Rentals Trench Safety team is committed to supporting you from the start of your project to its completion.

Our cutting-edge protective systems, industry-leading service, and operator training courses equip you and your team with the necessary equipment and skills to work safely and efficiently while complying with OSHA and provincial regulations.

Learn More About Our Trench Safety Training Courses

Get certified as a competent person for trenching and excavation work according to OSHA standards. Courses are available for competent person certification and confined space awareness.

Trench Safety Resources

Dive deeper into Trench Safety with these related articles, blogs, and success stories.